7th India International DRI & Steel Summit 2026 | Navigating the Sustainable Growth of Indian Steel Industry

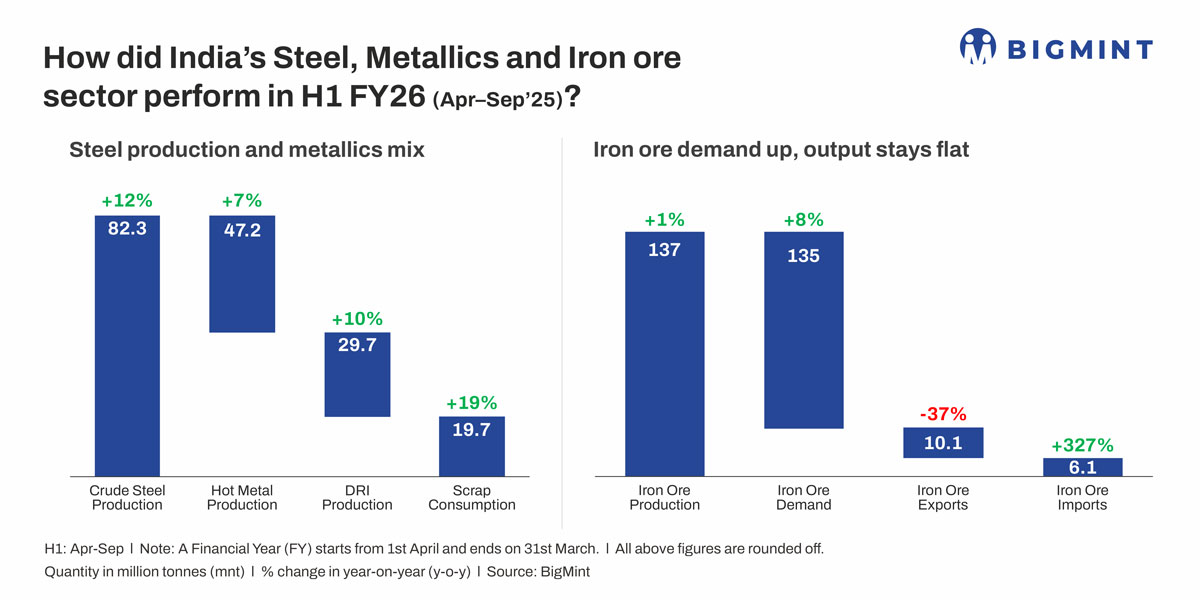

Steel has played a pivotal role in driving India’s economic growth, contributing significantly to the country’s GDP. The outlook for the Indian steel industry remains strong, driven by rising demand in key sectors such as infrastructure development, automotive manufacturing, and construction. In parallel, India’s Direct Reduced Iron (DRI) capacity is also on the rise.

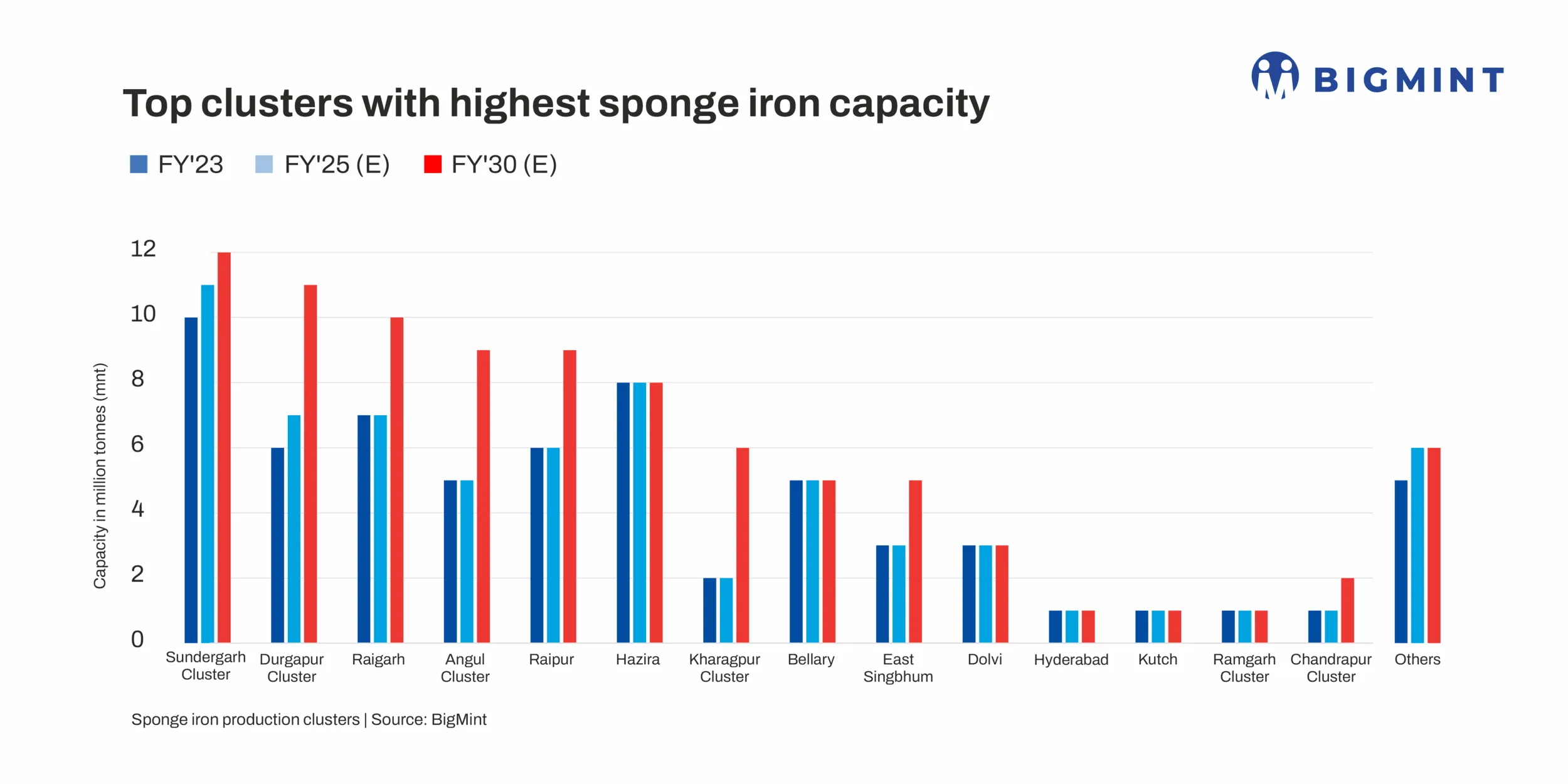

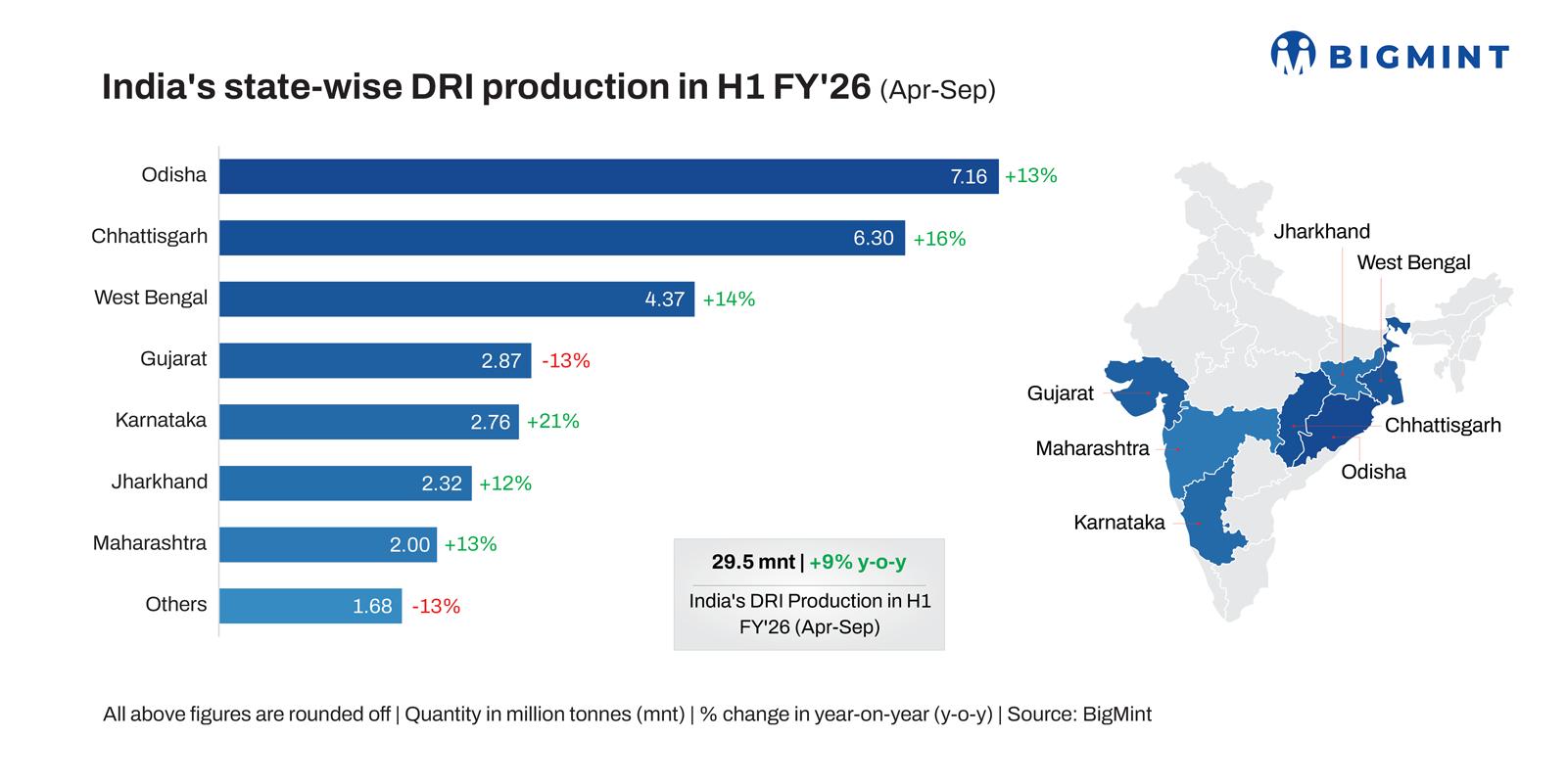

The DRI sector is projected to grow at a compound annual growth rate (CAGR) of 6% by 2030, with expected annual production reaching between 65 to 70 million tonnes by FY’30. As DRI capacity expands and production technologies improve, India is well-positioned to capitalize fast emerging requirements of metallics.

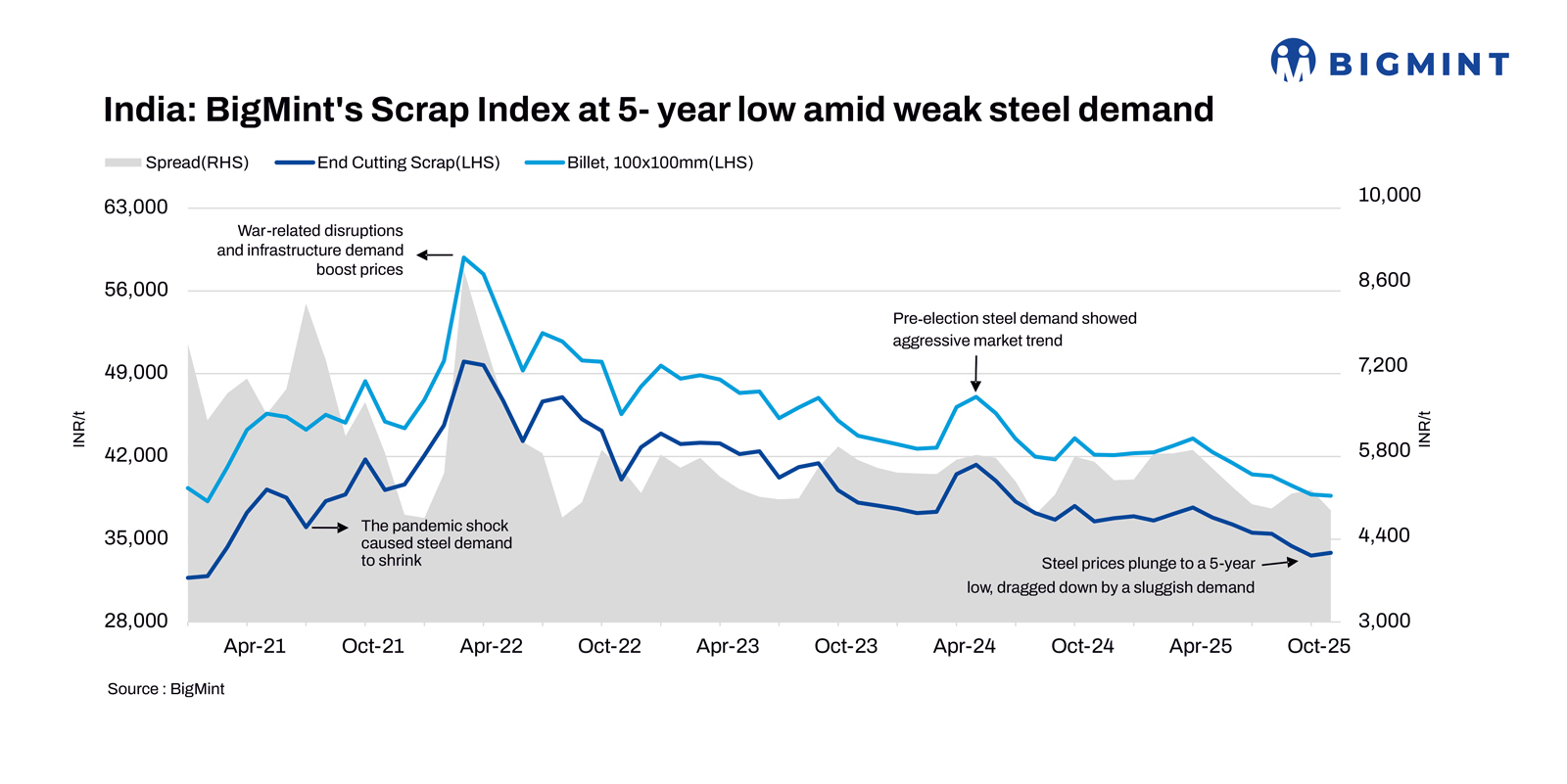

The global scrap market is constantly evolving, influenced by geopolitical shifts, trade policies, and environmental regulations, opening new avenues for Indian mills to import scrap from diverse sources. As India increases its steel scrap imports, it strengthens its potential to become a dominant force in the global steel industry. DRI and steel scrap together will fuel the Indian steel production.

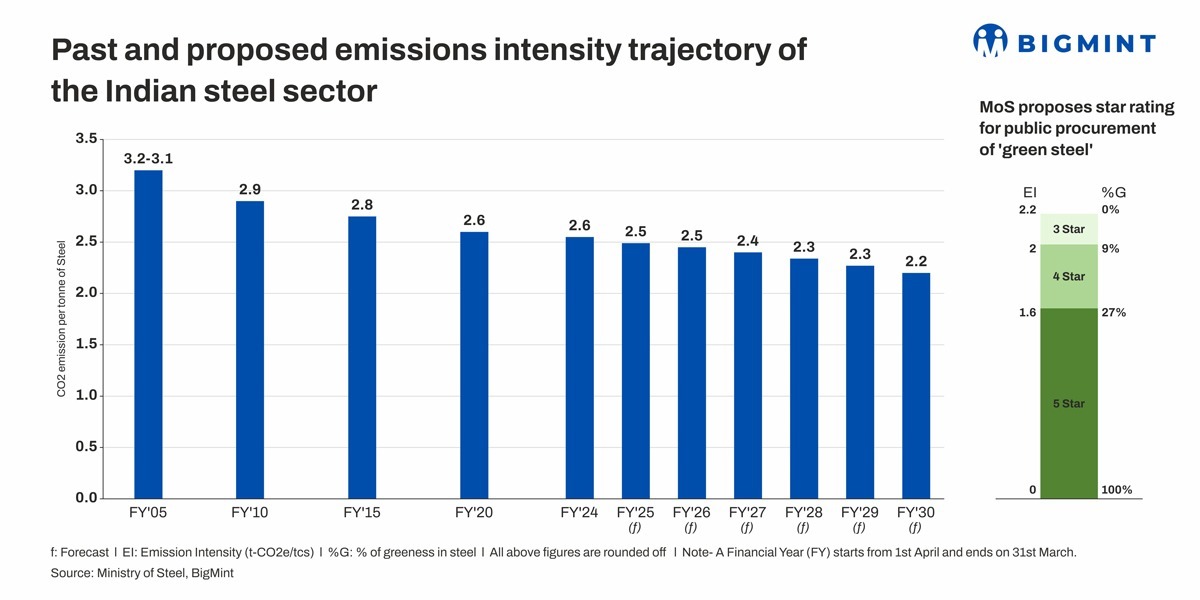

The Challenge of Sustainability

While the Indian steel industry is poised for significant growth, it must also address the critical challenge of sustainability. Reducing carbon emissions and transitioning to a greener production model are paramount for the long-term success of the sector.

About the Organiser

Sponge Iron Manufacturers Association

India took its first significant step towards economic liberalization in 1991. At that time, the country's economy was undergoing a radical transformation. In response to this changing landscape, the Sponge Iron Manufacturers Association (SIMA) was established and began its operations on 11th February 1992. SIMA's primary objective is to serve as a platform for the exchange of knowledge, experiences and growth-related insights within the industry.

One of SIMA's key roles is to provide a forum for reviewing the industry's smooth functioning in relation to Government policies, global developments and market feasibilities. As an apex body, SIMA also acts as an interface with the Government, advocating for and safeguarding the ever-growing needs of the industry in a rapidly evolving business environment.

Furthermore, SIMA is committed to maintaining an up-to-date database from both national and global perspectives. This ensures that its members are well informed about growth possibilities and prospects, enabling them to make informed decisions.

In summary, SIMA plays a crucial role in facilitating the growth and development of the sponge iron manufacturing industry in India. By fostering knowledge exchange, advocating for industry needs, and providing valuable insights, SIMA contributes to the industry's success in an increasingly competitive global market.

Knowledge & Marketing Partner - BigMint

BigMint is a trusted platform for price reporting, market intelligence and consulting for commodities. We enable our clients to take critical market decisions by providing a robust platform for pricing, data and networking. This keeps them at the forefront of the industry. We also provide networking and business platforms by organising conferences cutting across sectors and in different corners of the globe to enable stakeholders to come together and share their ideas, knowledge and exhibit products and services among their peers.

BigMint Events, formerly SteelMint Events, is a powerhouse in connecting all the stakeholders in the commodities space. Since 2014, we have hosted over 35 industry-shaping conferences worldwide, engaging over 15,000 participants. We bring together a diverse range of thought leaders including producers, buyers, sellers, and solution providers, fostering knowledge exchange and building a dynamic networking platform for professionals across the commodity landscape.

The data highlights the projected growth of sponge iron capacity across key clusters, with Sundergarh, Durgapur, and Raigarh leading the expansion by FY'30. Notably, the Sundergarh Cluster is set to maintain its top position, growing from 10 MTPA in FY'23 to 12 mnt per annum by FY'30. The Durgapur and Angul clusters show significant growth, indicating increasing investments in direct reduced iron (DRI) production.

Connect with top industry leaders!

Grab the participant list now!

Head - Department of Metallurgical Engineering and Materials Science

IIT Bombay

Practitioner Development Economist, Former Secretary Steel

Practitioner Development Economist

If you want to attend this conference and participate in the programme, then please hurry and register now!

Register NowIf you attended previous conferences and want to participate in the programme again, then please hurry and get your Download Previous Participants List!

Click Here20-November-2025

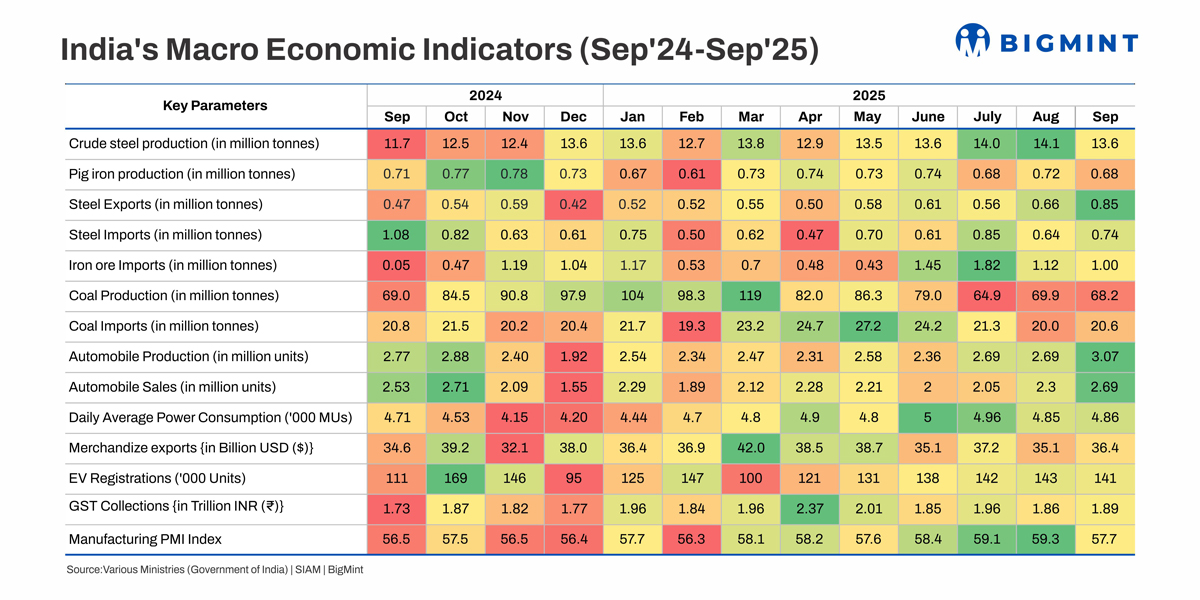

Manufacturing PMI slides to 4-month low Crude steel production drops by 4% m-o-m GST cuts, festive demand boosts auto salesMorning Brief: India's steel industry witnessed sustained growth in September 2025, albeit at a slower pace. While crude steel...

20-November-2025

Around 80-85 steel companies apply for certification Delay in formulation of GPP policy delaying green investmentsAs many as 80 to 85 steel companies in the country have applied for green steel certification under the Ministry of Steel (MoS), Govern...

20-November-2025

Domestic HMS prices drop INR 2,000-2,500/t since Aug25 Rapid growth in sponge iron output reshapes raw material dynamics Vehicle recycling poised to bolster long-term scrap availabilityMorning Brief: Indias domestic ferrous scrap market has plunged ...

20-November-2025

Odisha emerges as leading producer, with highest share Capacity expansions of 13 mnt announced in Apr-OctIndia's sponge iron production remained robust during April-September 2025 (H1FY'26), with the country maintaining its position as the world's l...

10-November-2025

Combined hot metal and DRI production increases by 8.5% y-o-y Scrap consumption shows robust 19% growth, iron ore output flatIndia's crude steel production witnessed a strong growth of 12.4% y-o-y in the first six months of FY'26, reaching 82.3 mill...

10-November-2025

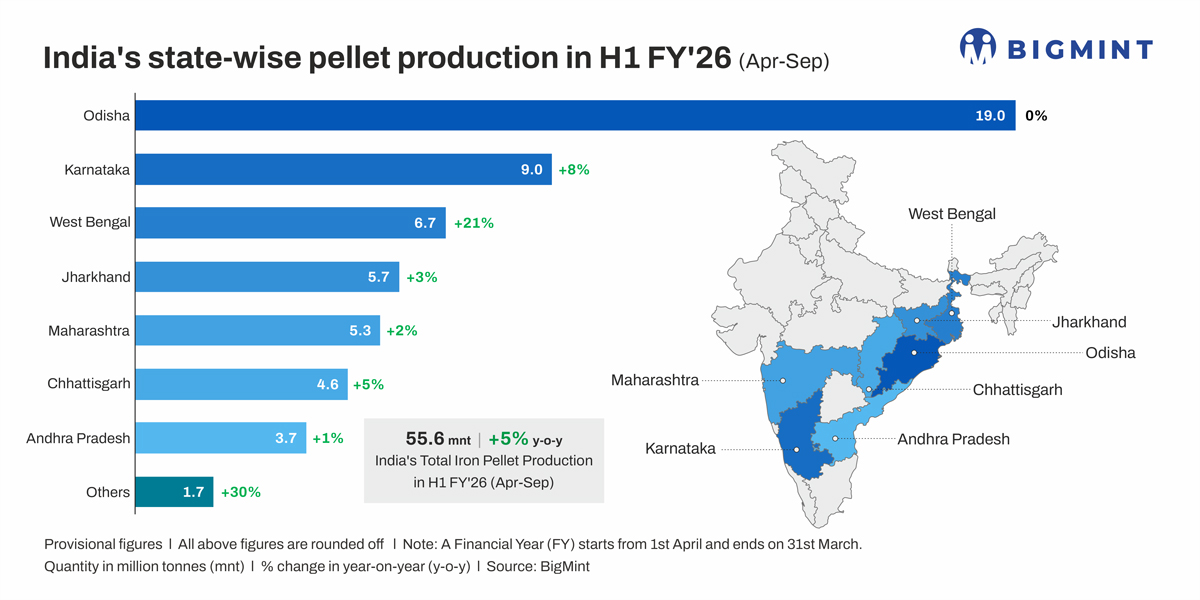

Production in H1FY'26 reaches nearly 56 mnt West Bengal records a sharp 21% surge in production Higher sponge iron production boosts pellet outputMorning Brief: Production of iron ore pellets in India in the April-September period of the current fis...

01-November-2025

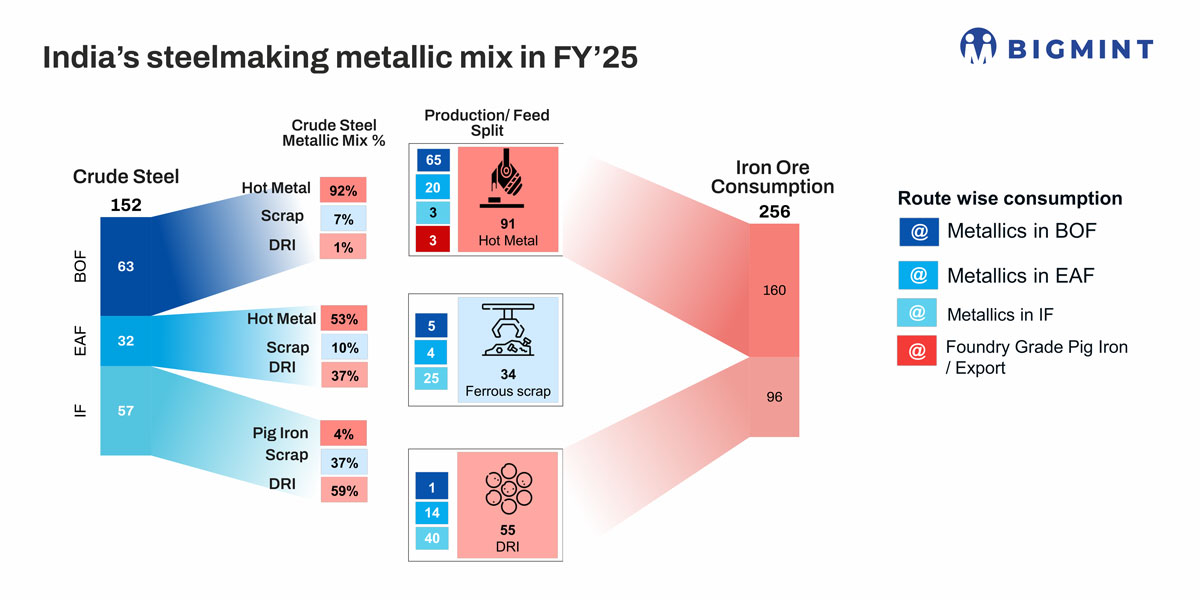

BF-BOF route makes for41% of crude steel output India produces 91 mnt of hot metal, 55 mnt of DRIIndia's crude steel production increased by 6% y-o-y to 152 million tonnes (mnt) in FY'25, with the blast furnace (BF)-basic oxygen furnace (BOF) route ...

Theresa Francis

+91 85279 81743

dkedsima@gmail.com

Muskan Gautam

+91-9179044111

muskan@bigmint.co

Pankaj Thakur

+91-9039322000

pankaj@bigmint.co

Kabir Raj Dubey

+91-9993931361

kabir@bigmint.co